A few basic concepts and definitions about fibre optic rotary joints (FORJ) A FORJ – (Fibre Optic Rotary Joint) is the optical equivalent of an electrical […]

A few basic concepts and definitions about fibre optic rotary joints (FORJ)

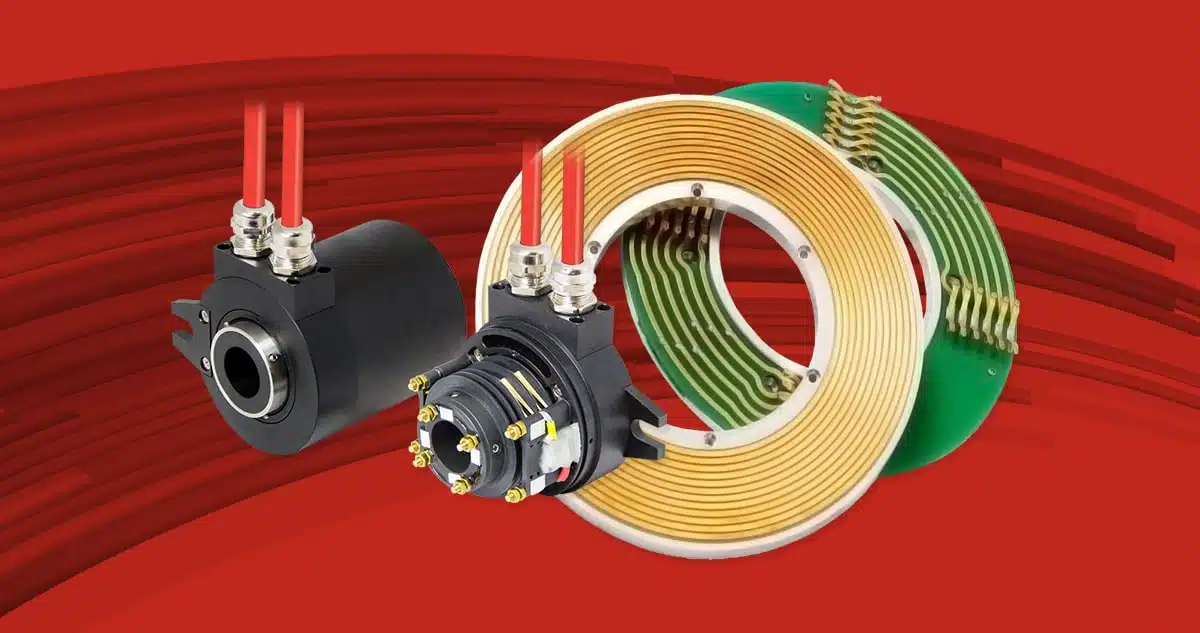

A FORJ – (Fibre Optic Rotary Joint) is the optical equivalent of an electrical contact ring, commonly called a Slip Ring. It provides uninterrupted transmission of an optical signal during rotation along the axis of the fibre. FORJs are widely used in missile guidance systems, robotics, remotely operated vehicles (ROV), oil drilling systems, detection systems, medical devices (OCT), communications in general and many other applications in the field which require fibre optic data transmission between a static section an another in continuous rotation, thus avoiding wear due to mechanical torsion.

1. Technology

A quick patent search will throw up innumerable FORJ patents, both two- and multi-channel. Only a few of these designs have been put into production, however. Our slip rings use technologies which facilitate both dual-port (2-channel) and multi-port (multi-channel) FORJs, thus offering our clients a high performance product.

2. Key parameters

The function of a FORJ is to transmit power and/or data between two or more optic fibre cables, while leaving them free to rotate relative to each other. It is thus essential that the device have a very low insertion loss, very little insertion loss variation (wow) and a high return loss, all parameters that characterise the amount of reflection generated by the FORJ itself, and hence its quality.

Let’s take a closer look…

Insertion Loss (IL): an insertion loss of 3 dB is equivalent to a loss of 50% of the transmitted optical power. The most commonly used multimedia converters offer an overall optical budget of more than 15 dB. However, multiple connections and components in fibre between the pair of converters can incur high overall losses; it is therefore essential to keep the insertion loss of the FORJs low. Our single-channel FORJs typically have an insertion loss of 0.5 dB, which rises to 3 dB for dual and multi-port joints.

Insertion Loss Variation (wow): variation in the coupling conditions will generally result in variations in the loss while the FORJ is rotating. However this variation (wow) must be kept low to prevent the signal to noise ratio degrading. Note that if wow is a critical specification for your application, you should choose one of our single-channel FORJs, which offer wow of less than 0.25 dB.

Wow is also used to measure the general condition of the device.

Return Loss (RL): all laser sources, especially distributed feedback lasers (DFBs), are sensitive to optical reflection, which causes spectral fluctuation and consequently power jitter. Return loss is a measure of the amount of reflection accumulated in an optical system. A reflection of -45 dB is equivalent to a return loss of 45 dB. While it is possible to obtain a return loss of 60 dB with singlemode fibres, multi-channel FORJs are typically rated for a loss of 40 dB.

A return loss of 40 dB is a standard requisite for single-mode passive components(like FORJs) to ensure that the system operates properly. All Servotecnica FORJs satisfy this requirement. We also offer FORJs with RL from 50 dB to 60 dB as standard options.

3. Single- or multi-channel

A single-channel FORJ has a very simple mechanical design which makes it very reliable and durable, compact and able to rotate at high speed.

It is also important to note that a single-fibre FORJ can transmit tens (and even hundreds) of data channels and, even when combined with a multiplexer, is much cheaper than a multi-channel FORJ.

However, if your application really needs a two-channel solution, Servotecnica offers co-axial FORJs which satisfy the most stringent requirements while maintaining a reasonable cost and compact size. Furthermore, our design does away with black spots.

Multi-channel FORJs necessarily have a much more complex mechanical design. They also require accurate optical alignment to maintain good performance in all the three key areas discussed above. Inadequate alignment or poor optical design not only compromise the key optical performance parameters, they also create new problems such as losses at high wavelengths, high PDL (polarisation dependent loss), high PMD (polarisation mode dispersion) and crosstalk (this is discussed further below). The multi-channel design of our slip rings can align up to 12 standard channels, in addition to a large number of personalisation options.

Wavelength dependent loss is a measure of the uniformity of insertion loss over a range of wavelengths, since multiple wavelengths, such as 850, 1310 and 1550 nm, are common. If the optical system contains a highly dispersive component, the wavelength dependent loss can be problematic. A difference in insertion loss of 0.5-1.0 dB between 1310 nm and 1550 nm is generally considered acceptable.

A similar effect to wavelength dependent loss is polarisation dependent insertion loss (PDL). In a typical fibre optic system, the input polarisation varies randomly. Less than 0.1 dB is the industry standard for passive components. It is also known that an optical component with a non-normal angle of incidence creates a high level of PDL.

The polarisation mode dispersion is the index of how much the pulses are stretched due to the difference in speed between the two orthogonal polarisation modes. Any birefringence, whether natural or induced, will cause PMD in the system. A value of 0.1 pico-second (ps) or less is the most common requirement for passive components. Note that PMD is not a significant factor except for bandwidths of more than 1 Gb.

Crosstalk measures the noise of electromagnetic interference generated between two adjacent channels. The higher the rating, the lower the interference. For example, crosstalk of 60 dB represents an interference between adjacent channels of 1 part per million.

The crosstalk rating varies from system to system, but one can say that the higher the optical budget of the system, the greater the crosstalk index should be. All Servotecnica two- and multi-channel FORJs typically have crosstalk rating of over 60 dB.

4. Singlemode vs. multimode

The very small fibre core (9 micron) of single-mode fibres keeps the optical bands in their purest form, a mathematically perfect Gaussian profile. The bandwidth capacity of single-mode fibres is much larger than that of multi-mode fibres. Their bandwidth is also much less dependent on the length of the fibre itself, and can easily be extended. Overall, multi-mode systems still have a cost advantage over single-mode systems. However, the gap between them is coming down as single-mode solutions grow in popularity.

5. Size

Size matters – as the history of passive fibre optic components demonstrates. In reality, ever smaller solutions have driven innovation.

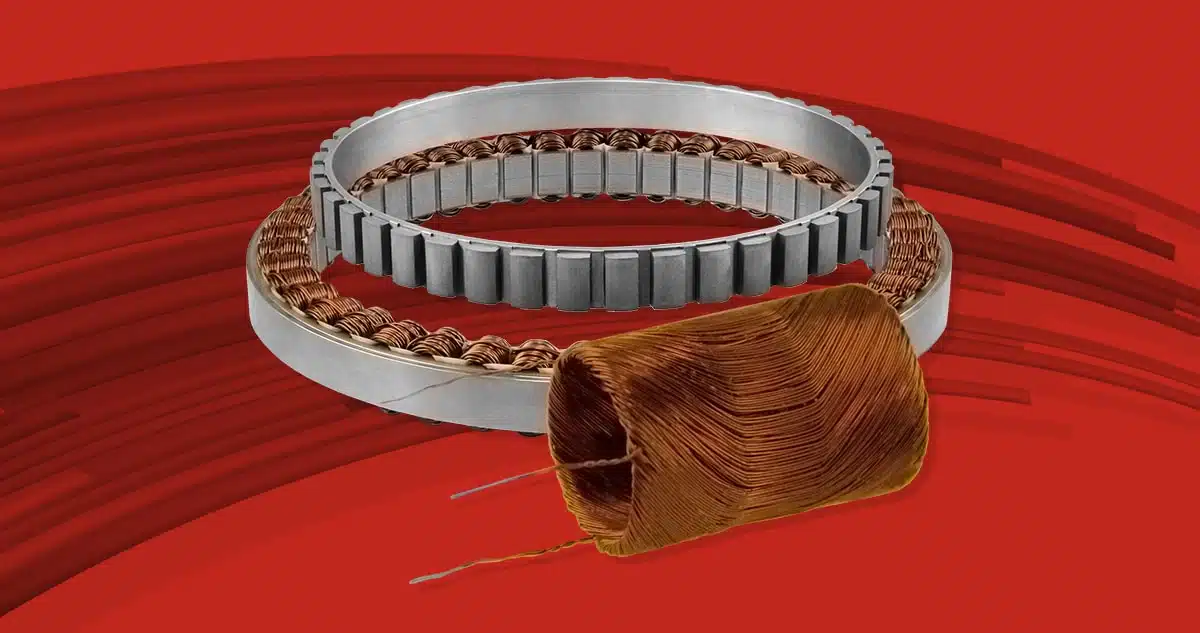

It is not uncommon to combine fibre transmission with electric slip rings, RF rotary joints or fluid rotary joints, with the FORJ at the centre of the system; this ensures that its diameter is a deciding factor in sizing the system as a whole.

Smaller FORJs reduce the cost of the entire system.

6. Fibre or female connector (pigtail or receptacle)

A FORJ may terminate in a free fibre (pigtail) or female connector (receptacle) at both ends of the device. In general, versions with a fibre pigtail have more repeatable optical characteristics, since they do away with the uncertainties inherent in joining connectors to each other. Furthermore, in the pigtail version, defective connectors can be easily reconditioned or re-terminated, while a similar defect in the receptacle version can easily be irreparable.

This is why we at Servotecnica generally recommend the pigtail version to the majority of our customers. However, for applications which do not permit the use of fixed fibre terminations on the device, our series R FORJs offer female connectors in the FC and ST formats. It is also possible to mix and match pigtails and receptacles in a single custom solution.

7. Through hole

Nearly all standard commercially available FORJs are supplied without through holes and, if they are present, they are not really passive FORJs , since they replace the output fibre with a photographic detector. Designing a passive FORJ with a through hole is very complex and challenging. Servotecnica offers a variety of passive models with through hole for a wide range of applications.

8. Fluid filling

FORJs are widely used in underwater applications, where waterproofing and pressure equalisation are critical factors. Filling the FORJ with fluid not only makes pressure compensation possible, but also provides lubrication and the correct index of refraction.

Servotecnica offers liquid and fluid filled models for all applications.

All our FORJs can be personalised to the satisfy the customer’s requirements.

Please get in touch if you don’t find the solution you’re looking for on our website, you’ll be pleasantly surprised by how we are able to make your work so much easier!