Bottle labelling machines are made up of a rotating carousel equipped with plates along its perimeter. The latters, thanks to either stepper or brushless motors, set […]

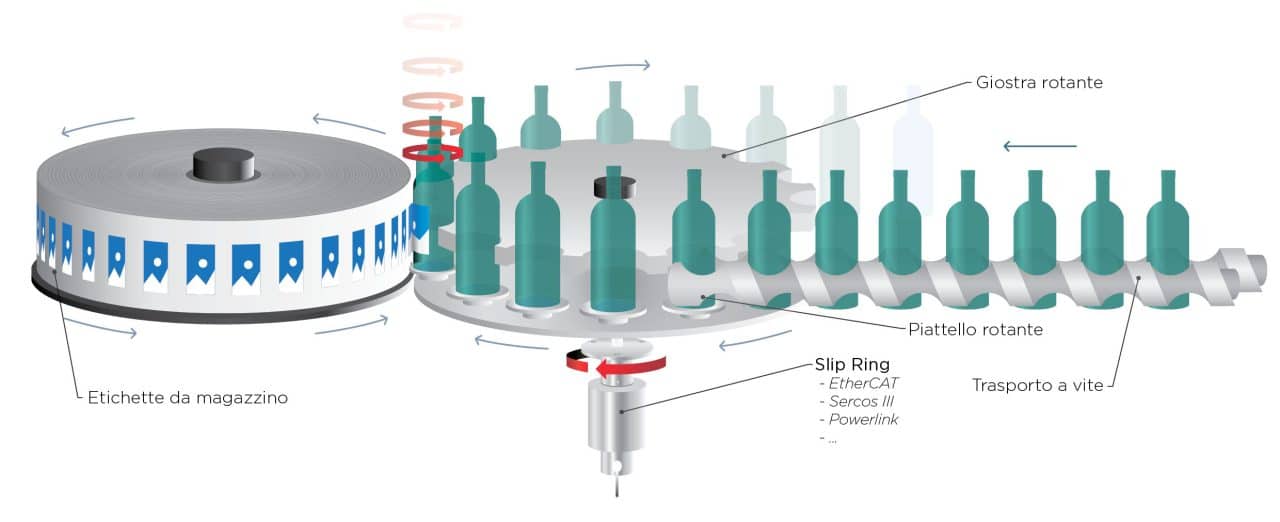

Bottle labelling machines are made up of a rotating carousel equipped with plates along its perimeter. The latters, thanks to either stepper or brushless motors, set the bottles placed on them in rotation.

The bottles are usually both moved forward and evenly spaced through a screw conveyor and so transferred on board of the carousel plates.

The rotation of the carousel brings the bottles to the labelling station and subsequently to the exit, in the meantime, the labels are picked from the warehouse, placed and wrapped around the bottles.

The labels taking and moving process towards the bottle, and the plate/carousel rotation are synchronised.

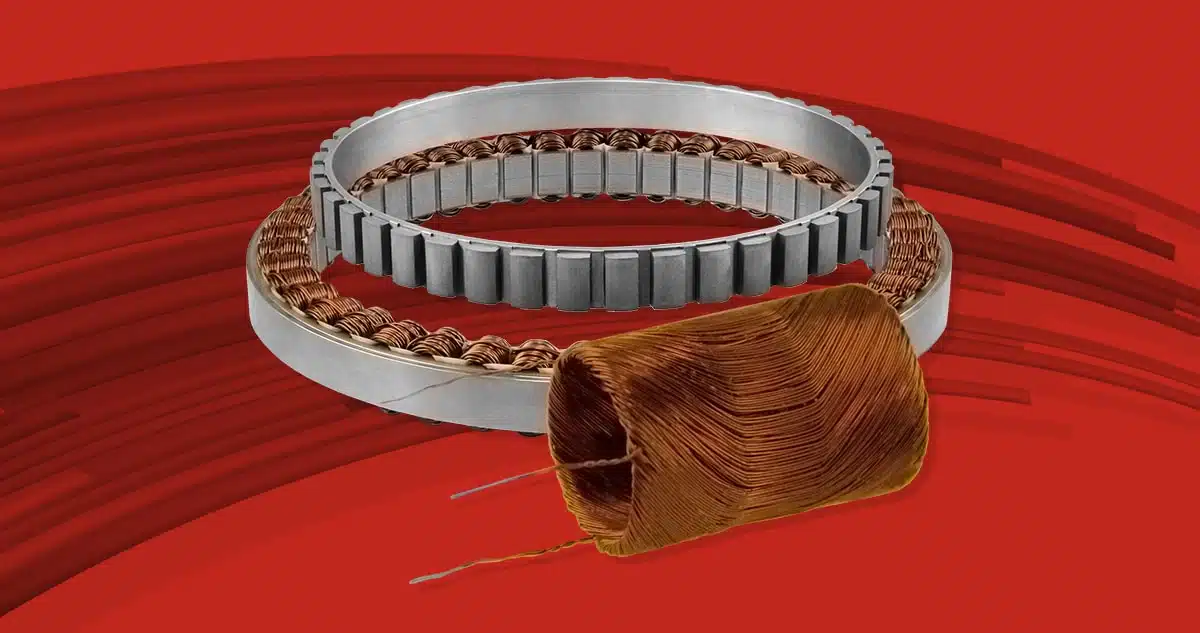

All the abovementioned synchronisation is obtained thanks to servomotors, drives and a specific software loaded on the motion control.

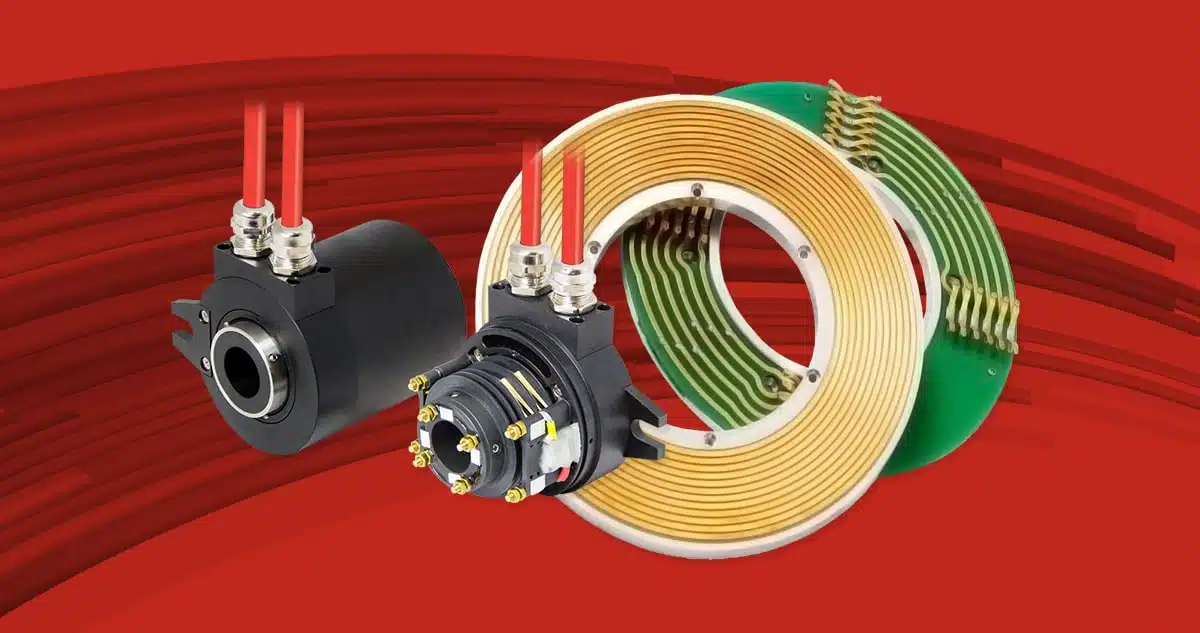

The majority of these components are located on board of the carousel and constantly rotate with it; for this reason, a slip ring is necessary to transfer power supply, controls and fieldbuses from the stationary structure to the rotating one.

Servotecnica’s range of products is able to transfer power supply, signals e high data-rate signals (EtherCAT, Sercos III, Powerlink, etc.) all at once.

In the event it is necessary to transfer on board fluids too, combined solutions, such as electric and fluidic rotary joints, are also available.