The inspection machines for the pharmaceutical industry detect the presence of impurities that contaminate the liquid contained in vials, ampoules, syringes, etc.. These machines comprise a […]

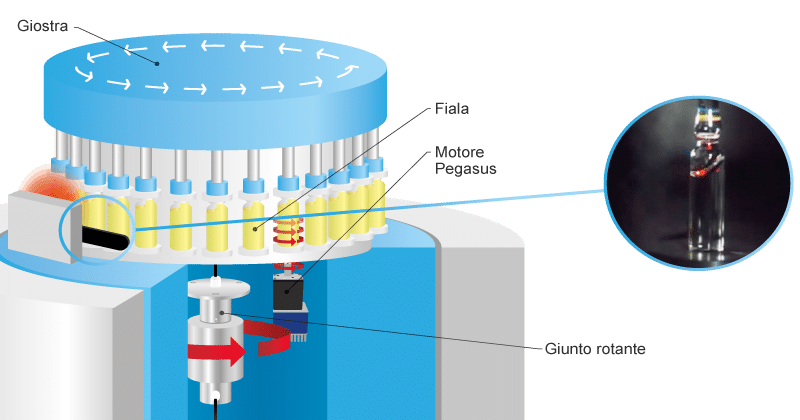

The inspection machines for the pharmaceutical industry detect the presence of impurities that contaminate the liquid contained in vials, ampoules, syringes, etc..

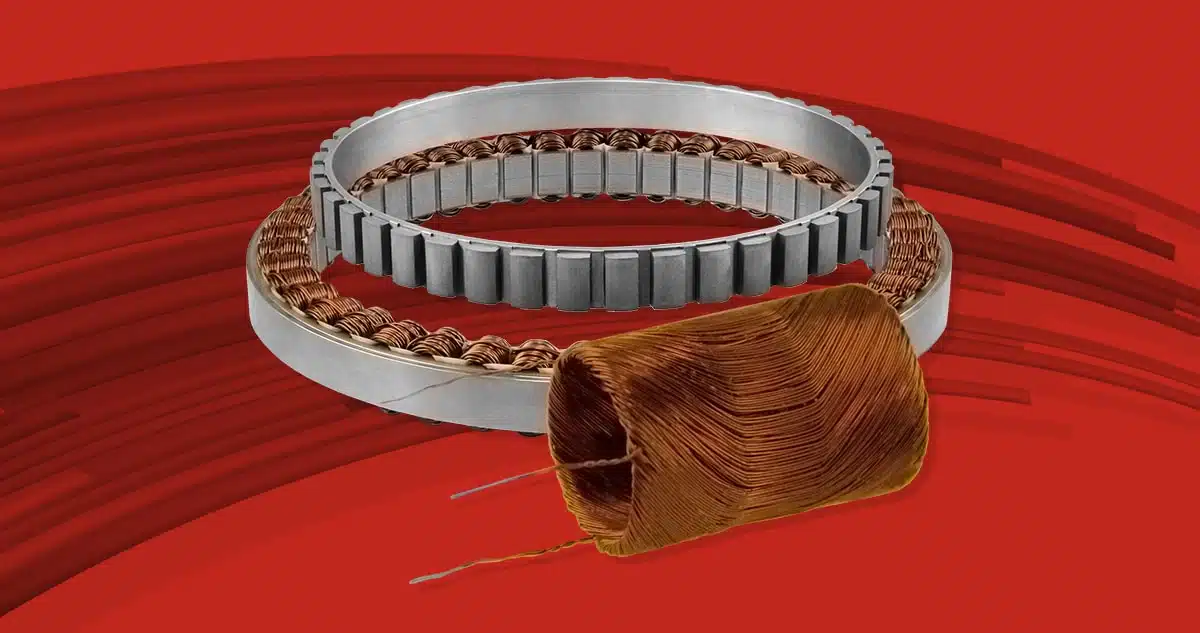

These machines comprise a central carousel on the perimeter of which are the plates that hold the vials containing the pharmaceutical liquid to be analysed.

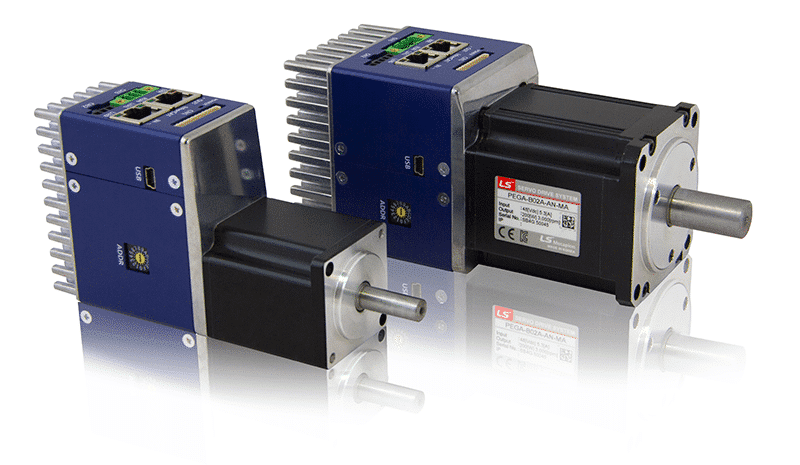

The carousel and plates rotate synchronously in the inspection system. The carousel is rotated by a servo actuator or a torque motor, the plates are thus already in motion and are rotated further by servomotors.

The movement of plate motor and the carousel motor is coordinated by a motion control.

The motion control (stationary) and the drives (in rotation on the carousel) communicate with each other via a fieldbus (CANbus, EtherCAT, etc.).

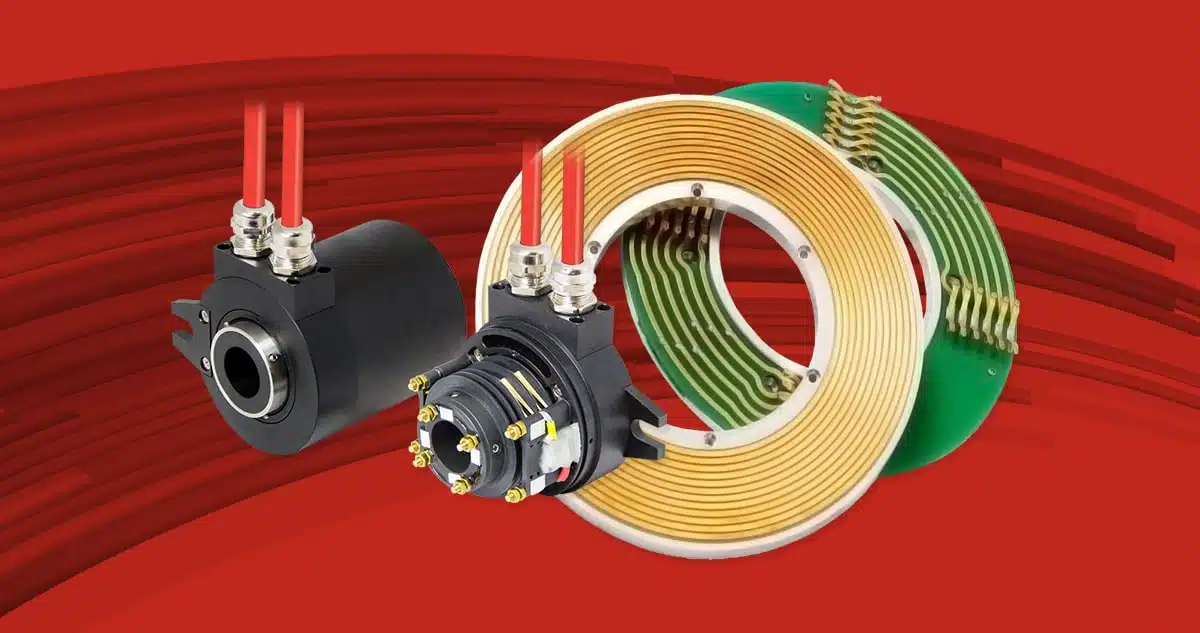

Consequently, it is essential to use an electric rotary manifold at the centre of the carousel to transmit the electrical energy required to operate the plate motors, the field bus which controls the drives and the various signals.

Servotecnica can provide servo motors with integrated electronics or electronics distributed to the plates, the servo or torque motor with drive for the carousel, the motion control and the electric rotary manifold to transmit fieldbuses with high data rate up to 100 base T EtherNET, Profinet, EtherCAT, Sercos III, etc.